Prepress and production tracking automation, document integrity and productivity reporting for print and mail operations.

Get instant access to real-time data that allows you to make executive decisions that will grow your business and customer relationships. Ironsides Nor’Star also improves productivity through highly detailed reporting that helps you better manage staff and machine throughput, reduce bottlenecks and eliminate errors. Most importantly, it ensures 100% distribution compliance, providing your customers with assurance that all of their jobs down to the piece-level have been assembled correctly, accounted for, shipped and are fully compliant with all industry rules and regulations.

Platforms

Ironsides AOT provides real-time visibility to all prepress operational activity for improved efficiency and time savings. The platform monitors and tracks the prepress process providing you with greater visibility into your workflow starting with order intake, through prepress and into the production process. Identify and track individual records, in real-time, as orders are received and move through your workflow. Comingle similar jobs for production batching while orders are in prepress helping to save costs, especially with ink jet printing. Detailed reporting helps prepress managers track jobs to identify potential bottlenecks and understand where and why rework was required.

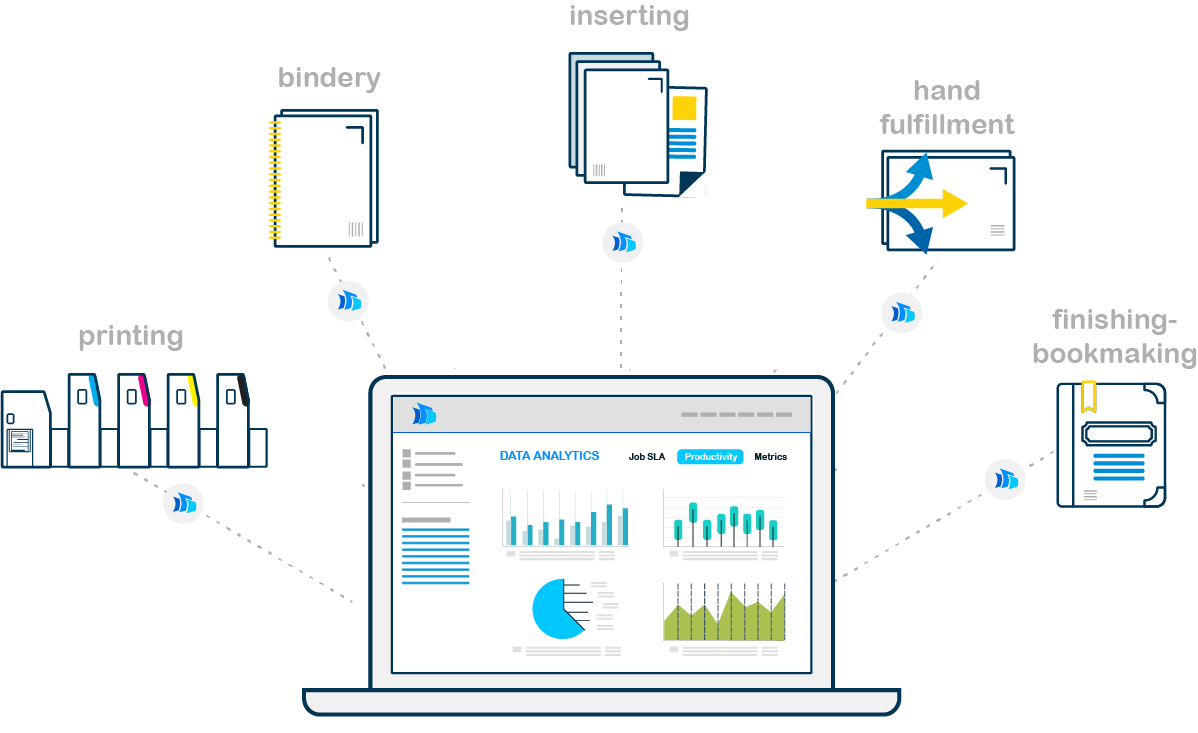

Ironsides APT ensures the integrity of individual pieces and complete jobs across multiple production lines while providing performance benchmarking information to optimize production. Ironsides APT tracks pages and collations being printed, finished, mailed and shipped, in real time, across all brands of continuous and cut sheet printers, ink jet printers, inserters, and finishing equipment. With Ironsides APT, you always have desktop access to work-in-process, production benchmarking, integrity accuracy and delivery metrics necessary to optimize business performance.

Ironsides ACA automates the collection of data from all your production steps starting with order intake through prepress, print production, finishing, bindery, sorting and mailing. Powerful data analytics and detailed reporting highlight the actual cost of each job, contract, or client. You have instant visibility into their true costs per day, week, etc. or by shift, equipment customer and much more. Ironsides ACA allows you to make more informed business decisions to drive profitability, grow your business and identify new application opportunities.

Automated Productivity Analytics (APA) is a tool that helps your operation monitor, measure, and optimize your print manufacturing operation. Using a wide range of data collection methodologies, it collects, analyzes, and presents key trends and productivity data such as OEE metrics, expected vs. actuals, efficiency, waste, downtime reasoning, and more. It’s ability to trend and easily present this data enables you to identify and resolve issues quickly, while improving efficiency, and increasing productivity.

Benefits

The Ironsides Nor’Star System provides you with the business intelligence required to improve efficiency, profitability and identify growth opportunities.

It is an easily integrated, highly scalable, real-time piece-level tracking and integrity reporting system. Ironsides Nor’Star allows users to efficiently manage production while ensuring the timely and accurate delivery of documents. 100% open, it integrates with existing prepress, composition, workflow, transformation and ADF products while allowing clients full access to the data. It is software and device independent and can be installed on any brand/model printer, inserter or finishing device. Developed to improve the operations and business performance of its users.

- Manage risk

- Job-level and piece-level tracking

- Reduce customer information breaches

- Improve facility and customer compliance

- Improve margin

- Group batch like jobs

- Reduce production and reprint costs

- Expand revenue streams

- Customer Retention – horizontal and vertical departments

- Provide new service offerings

- Create new customer opportunities in highly regulated industries

- Financial Services

- Government

- Healthcare

- Data consolidation

- One true command and control center

- Centralized reporting

- Open architecture, device independent

- Create a standard tracking solution

- Integrate with and adapt to current production devices/solutions

- Protect your investment

- Regulatory and contractual protection

- HIPPA, FISMA

- Avoid major quality disruptions

- Risk and security audits

- Elimination of manual processes

- Automated reprint

- Job/piece reconciliation

- Reducing human intervention and potential error

- Business Intelligence

- Manage daily production

- Job progress

- SLA manager

- Utilization reporting

- Operator

- Machine

- Facility

- Client specific reporting

- Audit reporting

- Manage daily production

- Printer

- API into controller

- Web Inspection/2D reader

- Job level tracking (work order scan)

- Bindery/Finishing

- Job level tracking (work order scan)

- Ability to integrate with existing tracking products

- Ability to install counting devices

- Insertion platform

- Ironsides camera installation

- Log file receipt from existing vision system

Interested in working together?

Let’s discuss your business technology needs and how we can help.